Your Ultimate Resource for Engine Rebuild Parts

When it comes to maintaining and rebuilding engines, the importance of choosing the right engine rebuild parts supplier cannot be overstated. The quality of parts you choose directly impacts the performance, reliability, and longevity of your engine. In this article, we will explore the critical aspects of selecting the perfect supplier, understanding the types of parts available, and ensuring that your engine rebuild project is a resounding success.

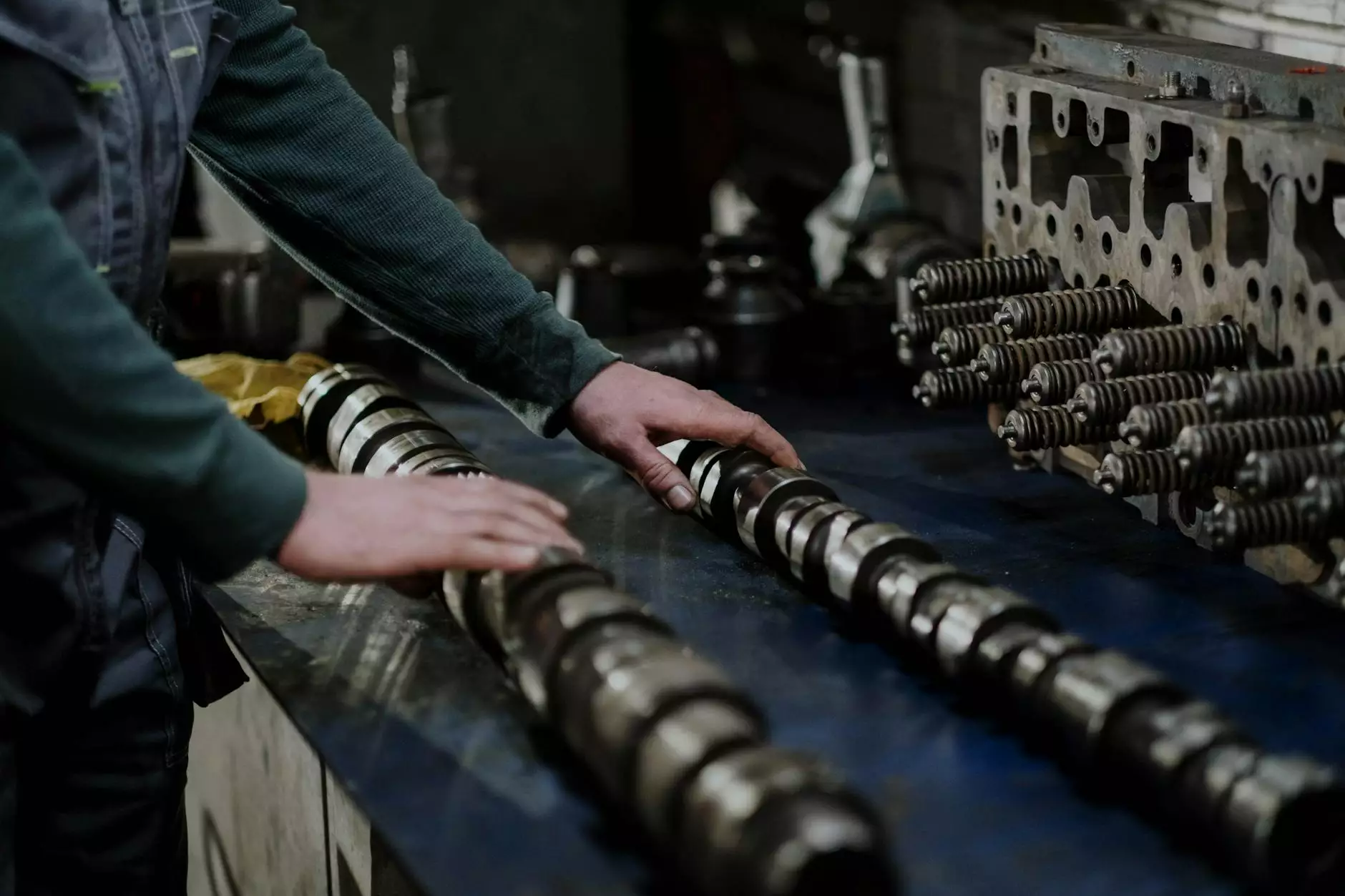

Understanding Engine Rebuild Parts

Before we delve into the specifics of selecting a supplier, it's essential to understand what engine rebuild parts are and their significance.

- Pistons: These components are vital for the engine’s functionality, transferring the force generated by combustion to the crankshaft.

- Rings: The piston rings help seal the combustion chamber, ensuring optimal pressure and preventing oil from leaking into the combustion area.

- Cylinders: The cylinders are the hollow spaces in which the pistons move. Maintaining cylinder integrity is crucial for a successful rebuild.

- Crankshafts: This is a fundamental part of the engine's rotating assembly, converting linear motion into rotational energy.

- Bearings: Engine bearings support the crankshaft and connecting rods, allowing them to rotate smoothly.

- Gaskets: These components create seals between various engine parts to prevent leaks and maintain pressure.

The Importance of Choosing the Right Supplier

When searching for an engine rebuild parts supplier, several factors will determine the overall success of your project. Here’s a closer look at these factors:

Quality Assurance

Your supplier should provide high-quality parts that meet or exceed OEM specifications. Low-quality parts can lead to premature failure, additional repairs, and wasted time and resources. Look for suppliers offering warranties on their parts, which is a good indicator of their quality.

Product Range

A comprehensive supplier will offer a wide variety of parts, including both OEM and aftermarket options. Versatility is key, as different engines and rebuild scenarios may require different types of components.

Expertise and Support

Choosing a supplier with extensive knowledge in the field can be invaluable. They should be able to provide advice on the best parts for your specific engine type and rebuild requirements. This expertise can help you avoid costly mistakes.

Pricing and Availability

While cost shouldn't be the only factor, it is an important consideration. Ensure that you are receiving fair pricing for the quality of parts you are purchasing. Additionally, the supplier should have a reliable inventory that guarantees availability when you need it.

Customer Reviews and Reputation

Investigating customer reviews and testimonials can provide insight into a supplier's reliability and service quality. Look for feedback on websites and forums, and pay attention to any recurring issues mentioned.

Testing and Certification

Reliable engine rebuild parts suppliers will conduct rigorous testing on their products. Parts should be certified to meet specific standards to ensure performance and safety. Make sure to inquire about testing procedures and certifications when evaluating supplier options.

Aftermarket vs. OEM Parts

One critical decision you'll face when selecting parts is whether to use OEM (Original Equipment Manufacturer) parts or aftermarket components. Each has its own set of advantages:

OEM Parts

- Fitment: OEM parts are specifically designed for your vehicle model, ensuring a precise fit.

- Quality: These parts often meet stringent quality standards set by the manufacturer.

- Warranty: OEM parts typically come with a warranty from the manufacturer, giving you peace of mind.

Aftermarket Parts

- Cost-Effectiveness: Aftermarket parts are usually less expensive than OEM parts, providing budget-friendly options.

- Variety: The aftermarket offers a vast selection of parts, including performance upgrades.

- Availability: These parts are often more widely available, especially for common engine types.

When deciding between OEM and aftermarket parts, consider your specific needs, budget, and the goals for your engine rebuild.

Essential Steps for Successful Engine Rebuilding

Rebuilding an engine is a complex process that requires precision and know-how. Here are essential steps to ensure a successful build:

1. Detailed Planning

Create a clear, detailed plan for your engine rebuild. Include the parts you will need, timelines, and specific goals for performance output. A well-defined plan can help you stay organized and on track.

2. Inspection of All Components

Before beginning the rebuild, inspect all components carefully. This will help identify any areas that may need extra attention or replacements. Pay particular attention to wear and tear signs.

3. Cleaning and Preparation

Thoroughly clean all parts to remove dirt, grime, and old oil. Proper preparation ensures that new parts fit properly and perform optimally. Consider using professional cleaning solutions for best results.

4. Installation of New Components

Follow best practices for installing new components. Refer to service manuals for torque specifications and installation procedures. Don’t rush this process—accuracy is key!

5. Testing the Engine

Once the engine is rebuilt, conduct thorough testing to ensure everything functions correctly. Monitor for unusual sounds or leaks, and verify that performance meets expectations. Taking the time to test can prevent future problems.

Common Engine Rebuilding Mistakes to Avoid

Even experienced mechanics can make mistakes during an engine rebuild. Here are some common errors to be aware of:

- Neglecting to Research Parts: Skipping detailed research on parts can lead to incompatible components.

- Rushing the Process: Engine rebuilding requires patience; rushing can result in careless errors.

- Ignoring Manufacturer Specifications: Not adhering to specifications can lead to improper assembly and performance issues.

- Overlooking Small Details: It’s often the small details that can derail a rebuild, such as gaskets and seals.

- Failing to Seek Help: Don’t hesitate to ask for assistance or advice; two heads are often better than one.

The Future of Engine Rebuilding

As technology advances, the landscape of engine rebuilding is changing. Innovations in materials and processes promise to make rebuilding more straightforward while enhancing performance. Some trends to watch include:

- Increased Use of Synthetic Materials: These materials can offer improved durability and performance.

- Integration of Sensors and IoT: Future engines may include advanced diagnostics to facilitate optimal rebuilding practices.

- Eco-Friendly Solutions: A push toward sustainable practices will drive change in parts manufacturing and materials used.

Conclusion

Choosing the right engine rebuild parts supplier is essential for any successful engine rebuild project. By understanding the parts involved, evaluating potential suppliers thoroughly, and avoiding common pitfalls, you can ensure that your rebuild is executed smoothly and effectively. At imautoparts.com, we pride ourselves on being a top-tier supplier of auto parts and rebuild kits, ready to meet your every need. Invest in quality, invest in your engine, and watch as your automobile comes back to life with renewed vigor!